Menu

Service

ABS Edgings

Melamine Edgings

Real Wood Edgings

Aluminium Edgings

PP Edgings

T-Bar Edgings

Clamp-fit Edgings

Acrylic Edgings

Varnishable Edgings

PVC Edgings

Hotmelt Adhesives

Linoleum edgings

Furniture Luminaires

Handles

Knobs

Handle Elements

Handle Profiles

Handleless Systems

Wardrobe

Staircase & Balustrade Systems

Furniture Linoleum

Sibu Design Boards

Natural Surfaces

Wall design

Wooden Slats

Construction Profiles

Functional Profiles

Decorative Profiles

Carcass Connection

Universal Fastening Systems for Furniture

Angle and Flat Connectors

Worktop Connectors

Cabinet Suspension Brackets

Shelf support

Adjustment Systems for Seating Furniture and Beds

Plinth Systems

Mounting Solutions

Screws & Sleeves

Hinges

Flap fittings

Glass frames

Furniture Roller Shutters

Sliding Doors For Furniture

Fittings for Wardrobes and Cabinets

Drawer Systems

Extension Runners

Castors and Trolleys

Furniture Feet

Table Fittings

Office Management

Locking Systems

Silent Systems

Waste Separation Systems

Midway Systems

Plinth Panels

Shelving Systems

Edge Processing & Edging Storage

Workshop and Construction Site Supplies

Hand Tools

Ergonomic Tools & Aids

Polishing & Abrasives

Workplace Safety

Packaging

Processing Technology

Adhesives

Cleaners, Release Agents & Lubricants

Surface Correction

Backing & Lining Foils

Mounting Solutions

close

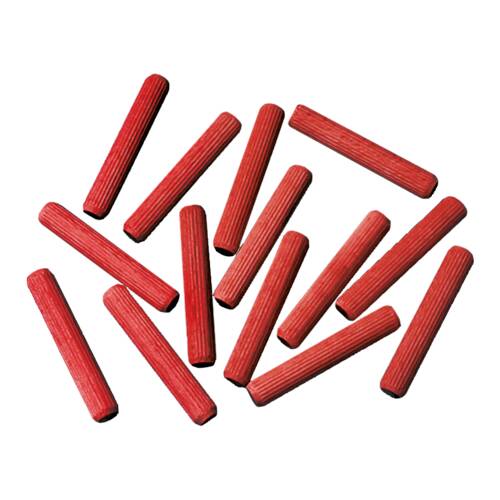

Beech dowels - REDOCOL, pre-glued

Accessory

Details

More information

Accessory

Details

Product description

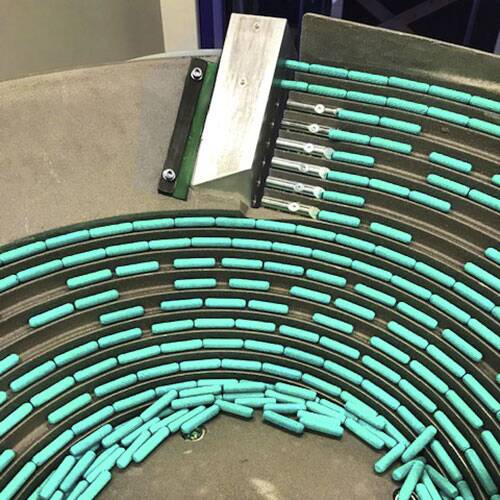

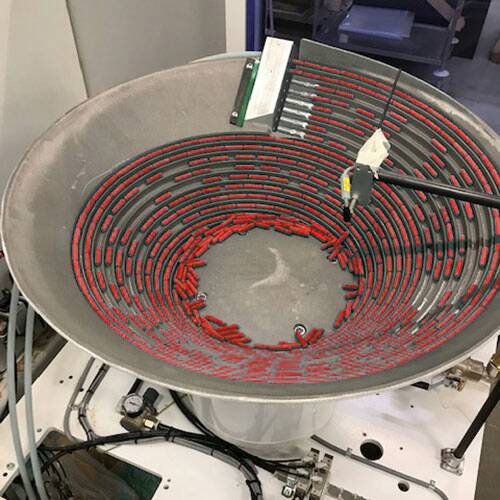

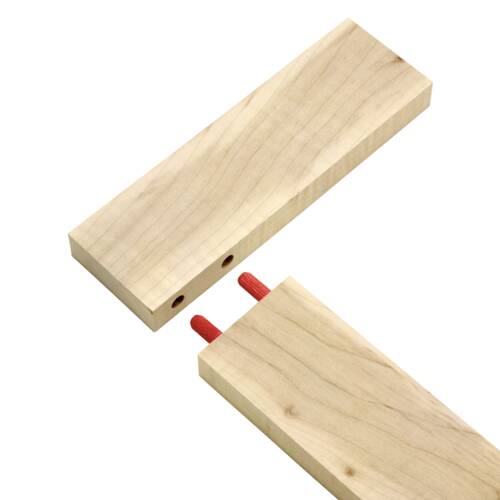

The pre-glued, fluted dowels made of non-steamed beech are chamfered on both sides and particularly suited for machine use and automatised furniture construction . They are coated with glue and then left to dry. Pouring water into the dowel holes during production activates the applied adhesive. This way, variations in dosing as well as surface soiling are avoided.

Product features

- Significantly lower glue consumption / no glue residue

- No clogging of glue nozzles due to processing pauses

- Reduced cleaning time

- Higher productivity

Tips

During production, the drill holes are filled by approximately 1/3 with water. The dowels are then pushed in manually or by machine, and the water activates the applied adhesive on the dowels.

Opened and closed packaging units must be stored in a dry place.

Product information

| Quality | DIN 68150 |

| Surface | Fluted, pre-glued |

| Type of wood | Non-steamed beech |

| Durability class in accordance with DIN EN 350 | 5 |

| Wood moisture content | 8 - 10 % |

| Assembly type | Is not repositionable |

| Ø | 8 mm |

| Ø tolerance | ± 0,2 mm |

| Tolerance length | ± 1 mm |

| Content per unit | 10 kg |

| Processing | Suited for machine processing with a dowelling machine or automatic dowelling machine |

| Press time | 15 - 20 min |

More information

Services

About OSTERMANN

Products

Information

Legal information

English

English