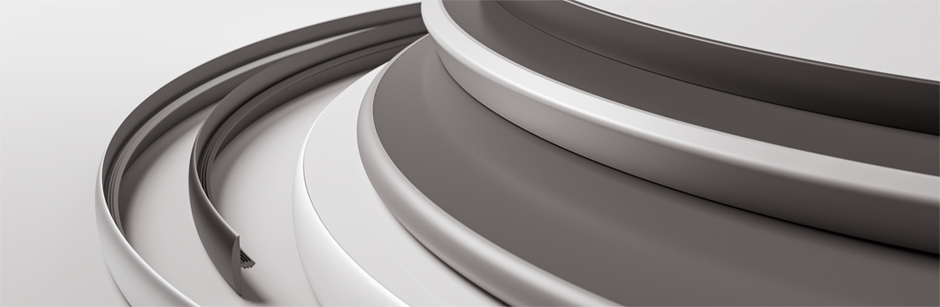

T-bar Edgings

Product Information

T-bar edgings are easy to process for an industry expert. The T-bar fitted at the back provides a temporary hold while allowing the glue to harden. The edgings are made of sturdy plastic or aluminium. Plastic T-bar edgings allow the manufacturer to manually edgeband tabletops and curved workpieces.

Selected profiles are also available in small quantities. The aluminium T-bar edgings are covered with a protective film to maintain the high-grade look.

PVC (polyvinyl chloride).

Lightfast, level 7 - 8 according to DIN 53387 (blue wool scale).

For lacquering thin surfaces, OSTERMANN recommends special varnishable edgings from the ABS and melamine range.

Normally inflammable according to DIN 4102, B2 self-extinguishing (B1 - hardly inflammable - only as a complete component, if LGA tested). Burning in conjunction with water and humidity produces hydrochloric acids.

Temperature-resistant from -40 °C to +100 °C.

Fulfillment of the chemical stress group 1B according to DIN 68861-1

Segregated waste is recycled by the manufacturer. Chipping waste with PVC residues can be passed to the landfill.

- Easy installation (with T-bar)

- Good protection

- Impact- and shock-resistant

- Radii possible

Tips & Tricks

When using T-bar edgings, glue should always be applied to the board. Excess edging can be removed using a router or even a chisel. In order to edge tight radii, make regular cuts in the barb. OSTERMANN offers the later attachment of a barb to standard ABS edgings.

Processing Instructions

Bond manually with REDOCOL Kantol greenline. Glue is not applied in the groove but on the narrow surfaces of the board.

T-bar to temporarily hold the edging until the glue hardens (no clamping required), curved crosscut for the perfect completion at the edge.

>18 °C

Depending on the different variants, different radii are possible.

Finish cleaner - possibly do not use strongly solvent-based or alcoholic substances.

In weather-protected environment nearly unlimited shelf life at room temperature (20 - 25 °C).

Surface damage can be mended with touch-up pens or hard and soft waxes.

ABS Edgings with T-bar

Upon request we supply 2 mm thick ABS edgings with retrofitted T-bars. This allows an easy bond of edgings to boards on site, and without an edgebanding machine.

- Cut a 3.5 mm wide groove into the board

- Knock the T-bar edging in after applying edging glue

- Trim after 1 hour and finish

- For straight boards, outer radii, inner radii and mitred boards

The T-bar can be fitted at the right- or left-hand side of the edging upon request, for the processing of mitred boards and protrusions.

Minimum order quantity: 10 m per colour and dimension Delivered in rolls of 35 m max

General Information

T-bars are covered with a protective foil and can be fitted on all our stock items. Special productions are non-refundable.

Processing Tips for Fitting T-Bar Edgings

Cut a 9 mm deep groove into the board by using a slot cutter. Apply the special edging glue, on the right and left side of the T-bar and knock the edging in with a plastic hammer. After approximately 1 hour the edging can be trimmed.

Attention

DO NOT apply the glue inside the groove, as it will soften the T-bar and prevent a strong hold. All of our 2 mm thick ABS stock edgings can be retrofitted with a T-bar. To achieve a minimum bondline, we recommend ordering a double T-bar edging for 45 mm and 100 mm wide boards.

English

English